The diamond bands of your dreams pass through many steps before they come to you. Diamond engagement rings, wedding bands and anniversary rings form with the help of experienced hands. These symbols of love and commitment take skill and several specialties to accomplish.

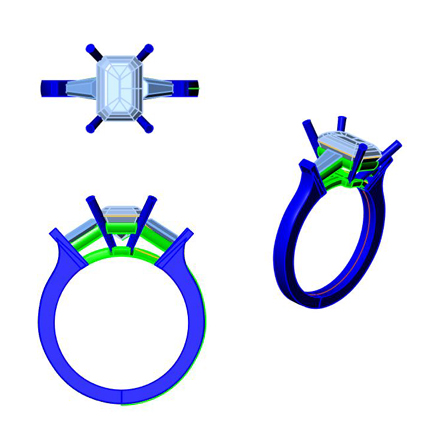

The first step is an image. Artists sketch the ring in detail, from multiple angles. This can be done on paper, with software, or both. The design is modified until it looks perfect. The earlier the stage, the easier it is to modify the ring.

Next comes a model of the ring, to get a clearer idea of how it looks in person. The band is carved from wax, settings and all. Complex designs may be 3D printed. Faux jewels complete the replica. Imperfections such as burrs are smoothed away. As with sketches, early modifications simplify later steps.

The model becomes the basis for an initial mold. With the help of lost wax casting, artisans create a second, stronger mold. Precious metal is melted and poured inside. Once cooled, the ring is removed and trimmed of excess material from the casting process.

While the ring takes shape, cutters transform diamonds from rough to jewelry-ready stones. Planners examine the rough to determine the best means to cut. After this step, specialists cut the diamond into shape and gradually add facets. A final polish helps increase brilliance.

Setting unites diamond and band. Sometimes the mount is molded into the ring, such as prongs. Other styles, like channel settings, are cut from the shank. In all versions, precious metal from the ring holds the diamonds in place.

After the ring is completed, it’s cleaned to bring out more shine. Depending on the band, it may go in an ultrasonic cleaner, where soundwaves loosen debris. High powered steam jets are another method. Once the ring is clean, it’s ready for your eyes.