Valentin Magro New York is an experienced in house jewelry manufacturing studio. Our services range from production for designers, galleries and exclusive retailers with the utmost attention placed on quality and detail in the manufacturing and to the sourcing of fine gemstones.

Go to Collections Contact Us

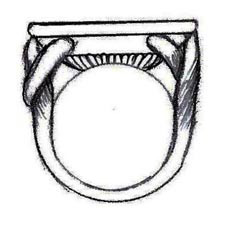

Manufacturing Our Jewelry – Our manufacturing process is every bit as intriguing as our designing methods. Thanks to technology, our sculptors no longer have to work with wax to curve out the molds of the design. We leave that part to computer aided designing and 3D printing to handle.

Casting – The crafting process starts after our jewelers are handed the wax molds created through 3D printing. At this point, we douse the resin models in plaster to create a hard outer cast. This cast we incinerate through a process that is called the burnout.

Curving – Our jewelers do no use the tools and technologies of yesterday. That said, they do not melt the metal using hand-held torches but through induction that is many times more effective than former. Another effective method we use to smolder our gold and platinum is high frequency melting which does the job really fast saving a lot of time and energy in the process. Our casting chambers are electronically equipped to control the temperature and environment required for a certain job.

Assembling – Additional settings and pieces are put together in the next step with the help of torches. For stone-based products, we like to use laser to weld and solder the parts and settings. That gives us greater control over the heating and melting of surrounding areas.

Setting – After this, our specialist stone setters place the loose diamonds and other gems and level them precisely before they are tightened using either pressure or prongs.

Finishing – Finally, at the last stage, we finish the polished through a multi-stage method. Polishing machines and hand-held shafts are used to deburr the pieces. This brings about the right kind of finish with a high level of accuracy in a short amount of time when handling small and delicate items like diamond bands.Here we buff the metals using soft rotary equipment and polish them to achieve luster to the desired level.